Software

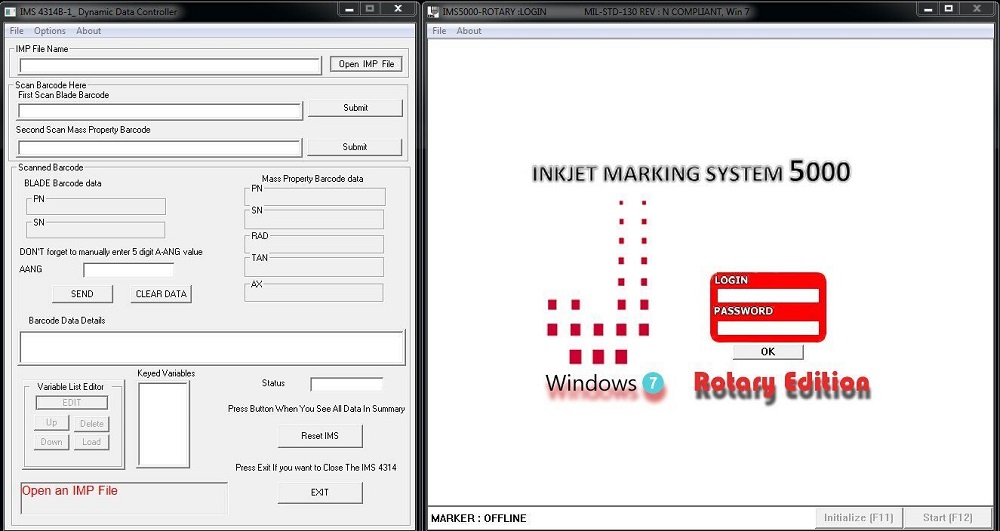

JETEC understands that manufacturers are looking to standardize their parts marking processes across multiple production lines, facilities or divisions. Each production area may have several industrial ink jet printers from various suppliers (Domino, Markem-Imaje, Leibinger, Videojet, Keyence, etc.) at their site but desire control of these printing devices remotely using a PC or web based central software. In addition to printing devices, manufacturers may want to read a 1D/2D bar code from a work order, have the marking program for that product type be automatically selected and then have product specific variable information downloaded into the marking program. Printed machine readable codes may need to be verified for Mil-STD 130 compliance prior to removing the product from the marking station. For those manufacturers who have purchased ink jet printers or integrated X/Y/Z equipment from ink jet manufacturers or systems integrators and are not satisfied with the performance or capabilities of their purchase the solution may be to implement our IMStm Integrated Marking Application Software.

IMStm Software

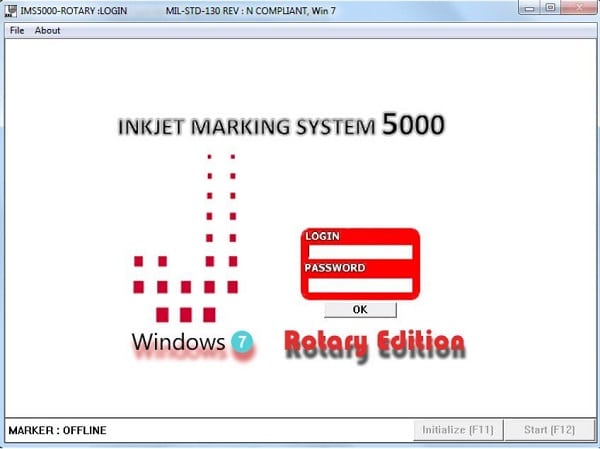

JETEC offers two IMStm Software configurations. One for fixed head systems, whereby the inkjet printer(s) or laser marker(s) will be stationary and the parts moved beneath the marker head. For fixed position applications, JETEC offers the IMStm 2701 Software. This software is capable of controlling numerous inkjet printers, laser markers, label printers, barcode scanners, 2D code readers, weigh and measure scales, UV curing stations, etc. The second IMStm Software is for moving print head applications, integrated systems with motion assemblies. IMStm 5000 Software was developed to provide inkjet and laser marker control, in addition to integrated devices safety light curtain, SMEMA conveyors, machine vision hardware, barcode scanners, X/Y/Z and theta motion assemblies and stop/start control hardware. If you purchased an X/Y/Z ink jet system from another systems integrator (Automation Plus, Videojet, etc.) most likely you can replace that system’s software with JETEC’s IMStm 5000. Contact the factory to see if it is feasible.

IMStm Software operates within the Microsoft Windows environment. It provides easy setup and control of individual part marking files. In most cases, using IMStm Software will extend the normal capabilities of industrial inkjet printers or laser markers. Using IMStm provides the user with the capability to print all standard Windows fonts, manipulate barcodes or 2D codes parameters based on specific substrates, print logos, images, custom date and time formats and comply with Mil-Std-130 UID requirements.

Other Software Development Services

JETEC offers software development services to provide complete application development and integration support. JETEC’s software development team can provide the IMStm Software in its standard configurations or customize the front end or provide enhancement capabilities to support your specific application. Over the past years, this team has solved some challenging product identification problems. Most modifications are in the form of device drivers for new types of equipment or hardware, application specific user interfaces or manufacturing database integration.

JETEC continually makes upgrades to the standard IMStm Software configurations. It is for this reason that JETEC strongly recommends IMStm users subscribe to JETEC’s Software Upgrade Support Service (SUSS). Active SUSS subscribers can obtain additional software support services at a reduced rate or in many cases, at no additional costs.